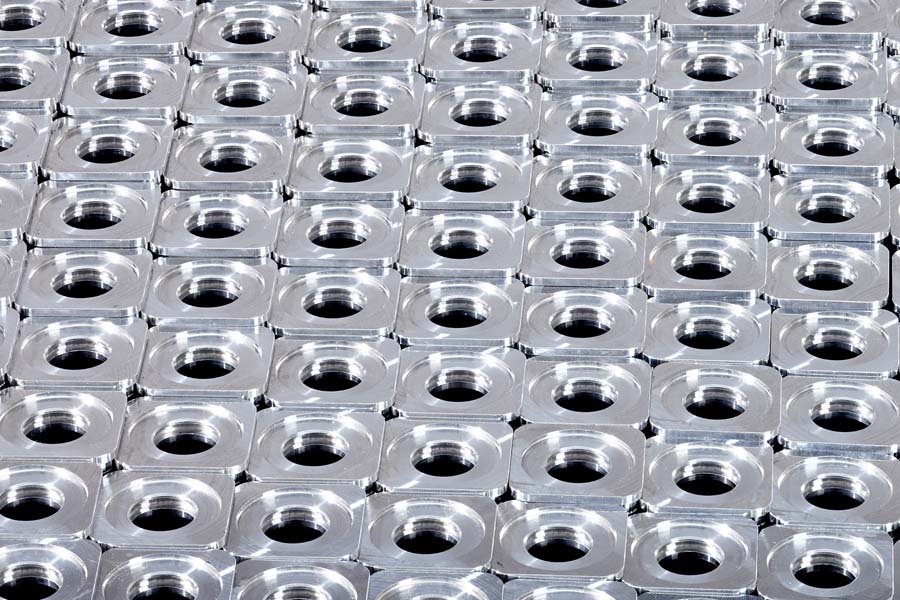

IMPACT EXTRUDED TECHNICAL COMPONENTS

The Impact Extrusion process can be used to develop components in areas where product integrity, lower unit cost, strength and reliability are key factors.

Impact Extrusion offers the flexibility to create cost saving features that can reduce material content, minimise secondary operations and remove additional assembly operations at your facility.

Applications include:

- water vending filters and softeners

- hydraulic cylinders and pistons

- lighting components

- drive units

- chemicals

- filtration systems/units

- automotive: coil cases, muffler cans, air conditioning, capacitor housings etc.

- any applications where near net shape is advantageous