All component machining is done in-house with a well-equipped modern CNC section:

-

twin pallet cnc machining for rapid processing times

- parts are loaded and unloaded with machine always running

- high speed spindles for rapid feed rates

- extremely repeatable and tight tolerances

-

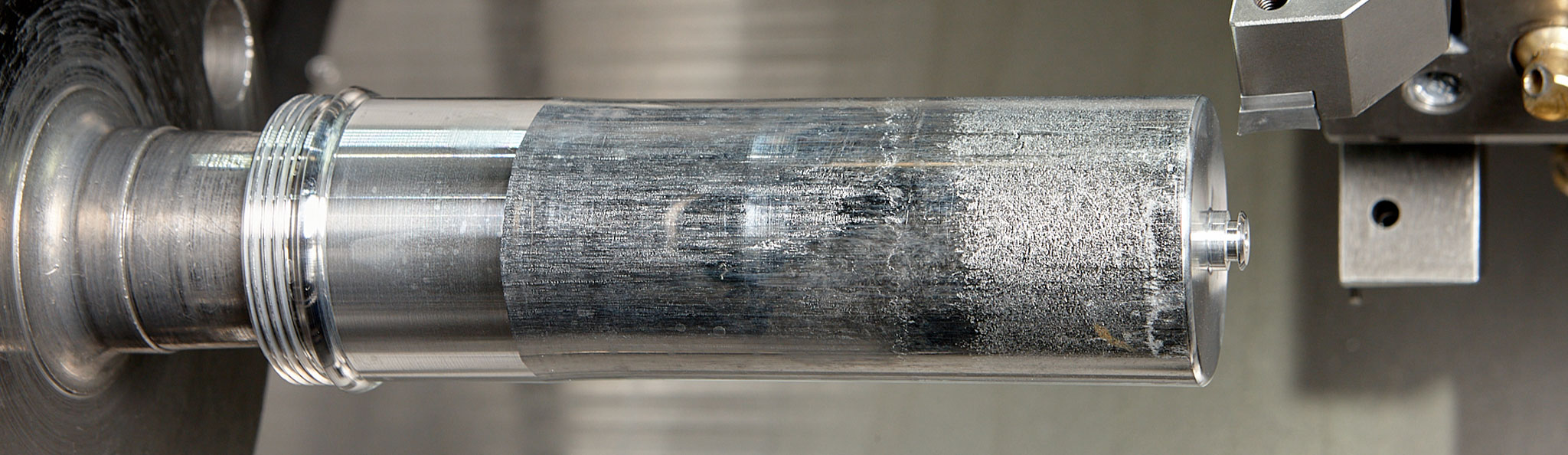

CNC lathes

- where tight concentricity tolerances are required

- for small batches to reduce tooling costs

- driven tools for milling / side features / side hole

Specialist tooling is used to reduce tool changes and increase machining rates to achieve the best possible cycle times for maximum efficiency. We regularly benchmark ourselves against industry best practice to ensure we are keeping up with the latest technology.